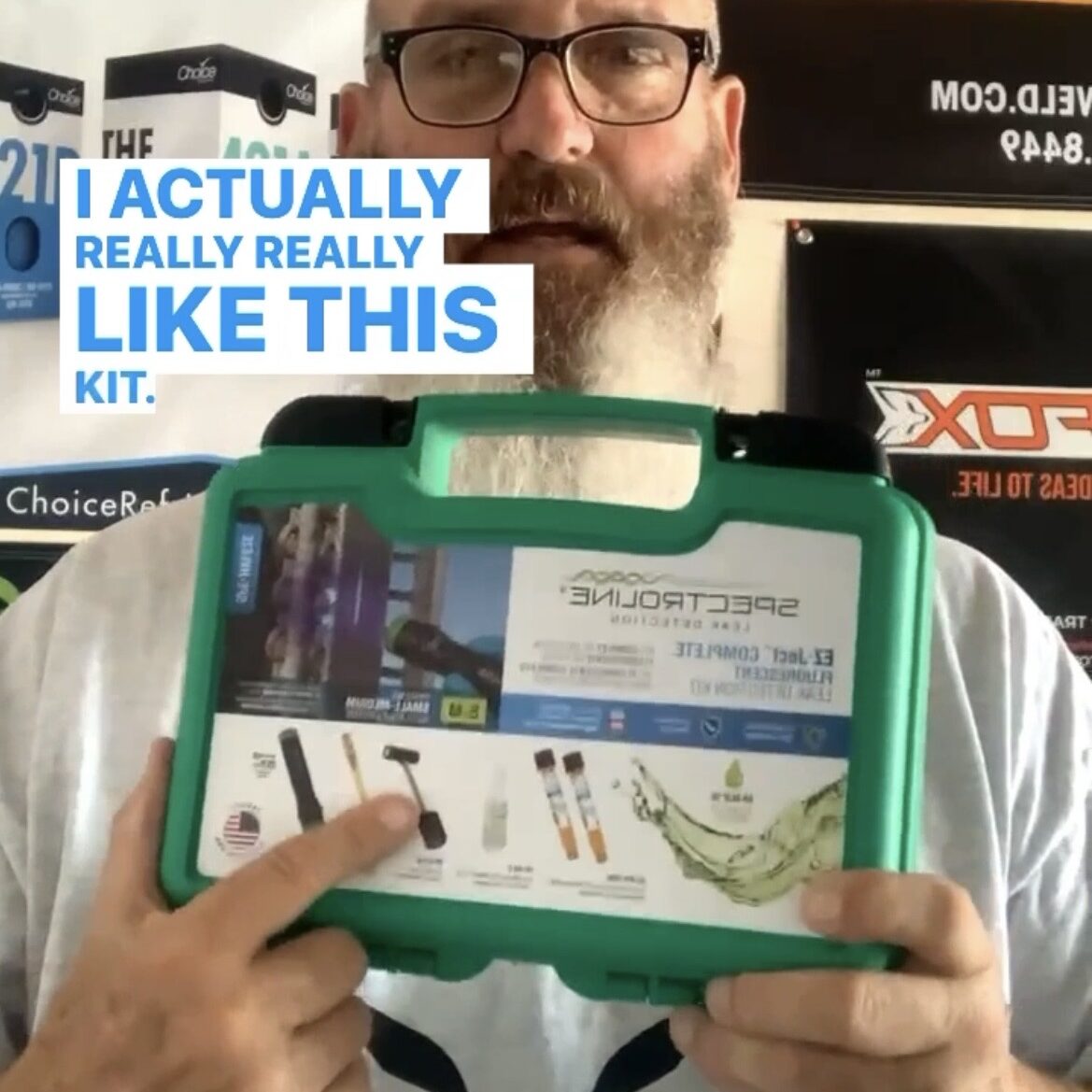

Spectroline Leak Detection is Exhibiting at ACCA 2024

We’re exhibiting our leak detection technology at the ACCA 2024 Conference! The ACCA Conference is the premier annual education and networking event for HVACR contractors. Stop by booth #508 to learn about our latest products and the NATE courses we offer! About ACCA ACCA is the only nationwide, non-profit association for professionals that install and maintain…

Details