Using WATER-GLO® to Find the Smallest, Costly Leaks

Within 10 Minutes of Adding WATER-GLO® Green to the System, the Leak was Found. Within 20 Minutes, the Leak was Repaired. RCM Spent $8,000 in Time and Labor Before Using WATER-GLO®

Actual image of spray patching

Gravel is then added to the patching spray to reinforce the repair’s strength and durability. The boom outfitted on the truck is equipped with a high-speed air vent. When applied, the high-speed air quickly dries and solidifies the amalgamation, ensuring the repair is complete.

These specially designed spray patching trucks go along tracts of roadway and quickly patch broken surfaces. But these trucks can only hold limited amounts of emulsified asphalt. RCM’s storage tanks allow the emulsified asphalt to be towed separately, supplementing the spray truck’s main supply. The storage tank is extremely useful on long and isolated tracts of roadway, and it is an essential addition to any repair fleet.

A Flaw in the System

Here’s the problem Frank Connelly’s team was facing: inside each of the emulsion storage tanks is a heat exchanger that allows the asphalt to be dispensed in a semi-liquid state. The storage tanks operate at temperatures up to 185 degrees Fahrenheit.

If the heat exchanger fails, the tank will overheat and the asphalt will then become unusable. Because these storage tanks operate at high temperatures, the water glycol used in the heat exchanger vaporates before leaks can be detected.

Trial and Error

The heat exchange coils within the storage tanks are constructed from schedule 40 piping and air-pressure tested to confirm a sealed system. When Frank’s team tried fixing the problem, they refitted the piping and pressure tested the system. But the pressure tests did not indicate any issues in the system.

After finding the air pressure tests results were normal, the team tried modifying the system to allow for extra capacity. The team modified the system with high-pressure rated valves. Frank’s team thought excess water glycol may have been forced out of system, during the high pressure and temperatures associated during prolonged operational use. Unfortunately, upgrading the system proved to be unsuccessful. The problem did not stem from the design to the tank – but a very small leak in the system that only became apparent during operational use.

Searching for Answers

Frank’s team kept trying to find the issue, but could not pinpoint the exact leak area. The team tried using a bubbling solution to locate the leak, but this method of leak detection failed. Frank’s team also tried isolating the heat exchange coils and testing them individually, but these efforts were unsuccessful as well.

Part of the problem was the asphalt: the viscous asphalt covered all parts and often hid leaks from plain sight. To a mechanic, it would be very difficult to spot the exact location of a leak in this messy environment.

The RCM team then asked the manufacturers of the storage tanks to inspect the tank itself for flaws. But the storage tank was fine. Other companies who purchased the same storage tanks never had an issue.

Frank and his team asked other companies in his line of work if they had ever experienced similar problems. But no one could give him an good answer or point him in the right direction.

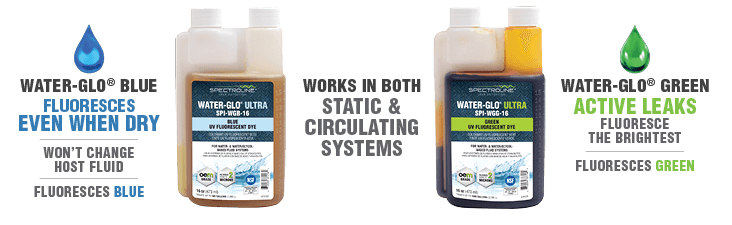

When Frank and his team were unable to reach a solution themselves, they searched online for help. In their search, the team came upon Spectroline® fluorescent leak detection dyes, designed specifically for industrial equipment. Intrigued by the positive feedback and testimonials, Frank ordered a sample of WATER-GLO® dye.

“We purchased one of your industrial (WATER-GLO®) leak detection kits…we found the leak in the coil within 5 minutes, our team could not believe how well the dye showed up….It is now a standard procedure to add (WATER-GLO® green) dye to the heating systems of all our tanks and run them for 24 hours to check for leaks prior to delivery.”

– Frank Connelly, RMC Equipment Company LLC.

Solving the Problem, Quickly and Accurately

Within 10 minutes of adding Spectroline® WATER-GLO® dye to the heat transfer system, the leak was clearly visible. Within 20 minutes, the fault was welded and the emulsion tank was fixed. The water-glycol stopped escaping from the system during operation.

The leak was within a 2-inch heating coil. Since the coils are custom welded, the margin of error for this specific part was larger than all the other parts of the system combined. And although the part was more likely to fail, finding its exact location proved to be a costly hurdle.

One thing was made clear during this ordeal: looking for faults with the naked eye didn’t work and proved to be expensive and time consuming.

Out of the many leak detection methods Frank used, only the specially designed WATERGLO® series dyes for heat transfer fluid system applications found the leak- successfully and within minutes of the initial application.

The Future of RCM’s Manufacturing

In total, Frank’s company spent about $8,000 dollars trying to find this leak. The financial losses added up in terms of wages, wasted materials, and the lost time. After discovering the issue could be resolved quickly, Frank is now a staunch supporter and advocate of Spectroline’s line of WATER-GLO® dyes.

RCM uses WATER-GLO® in their Quality Control Procedure. They add fluorescent leak detection dye to the system and allow it to run for 24 hours. Future leaks will be easily identified and fixed in a short amount of time, with little loss in materials and labor.

The Spectroline® Advantage

Part of the solution process, outside of the superior quality of the dye being applied, was the quality of the lamp being used to detect the dye’s fluorescence. Frank and his team used one of Spectroline’s compact but powerful ultraviolet leak detection flashlight. The flashlight is cordless and can be used in the tightest, hardest-to-reach spaces.

The RCM team was especially amazed how easy the application process was. The team simply added the dye, ran the system for a limited amount of time, and the used the Spectroline leak detection flashlight to identify the leak area in question. Within minutes, the team detected the leak area. In future, thousands of dollars will be saved during the manufacturing and quality control process – guaranteeing RCM’s end-product is flawless and completely satisfactory.

Spectroline’s patented fluorescent dyes provide superior leak detection and are trusted by major OEMs such as Caterpillar, Bobcat and Komatsu. Companies like Frank’s can hugely benefit from introducing Spectroline’s expansive and targeted array of leak detection dyes to their manufacturing process. Whatever the situation, Spectroline has come up the best and most reliable solution.

Protect your equipment. Reduce downtime.

Become a Spectroline Insider and Stay Updated:

- Preventative Maintenance is key to saving time and money

Learn about the best maintenance practices and asset management tools. - Optimize your business and become an innovator

Ultraviolet fluorescent leak detection technology provides 100% accuracy.