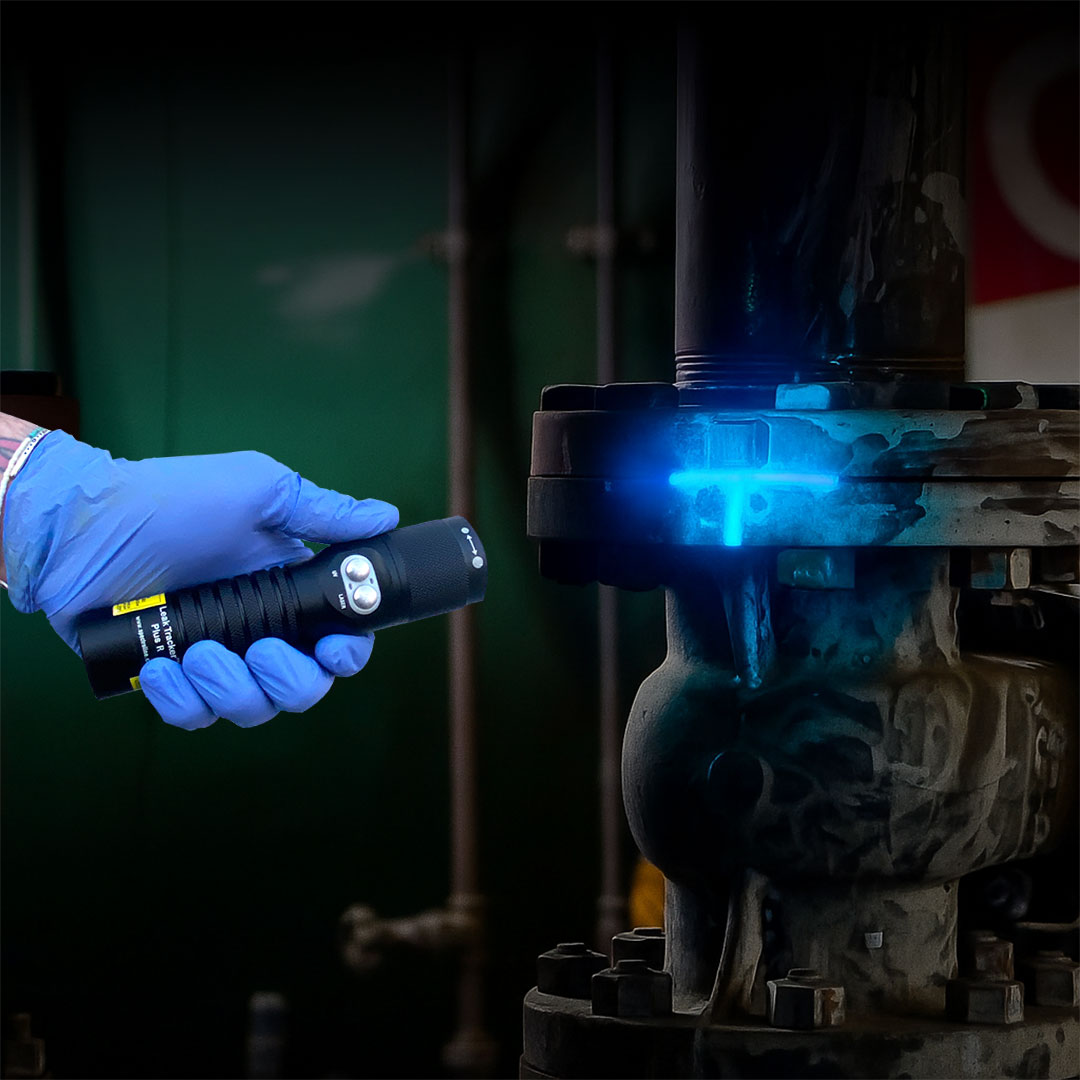

Unhandled HVAC Leaks Will Cost You. Prevent HFC Emissions and Cut Energy Costs with Spectroline

How much do HVAC refrigerant leaks harm the environment? HVAC leaks harm the environment a ton! HVAC refrigerant leaks have an astronomical climate impact even at small quantities, and they also waste electricity. Here’s how HVAC refrigerant leaks hurt the planet: Direct (refrigerant) impact. Many HVAC refrigerants are potent greenhouse gases. For example, EPA lists…

Details