How to Detect Silicone Oil Leaks with Spectroline OIL-GLO® Ultra Blue

Silicone fluids are essential across many industrial sectors, thanks to their exceptional thermal stability and chemical resistance. They’re commonly used in heat transfer systems, dielectric coolant systems, and as high-performance lubricants. But like all industrial fluids, silicone oils are prone to leaks, which can cause serious safety, environmental, and operational problems.

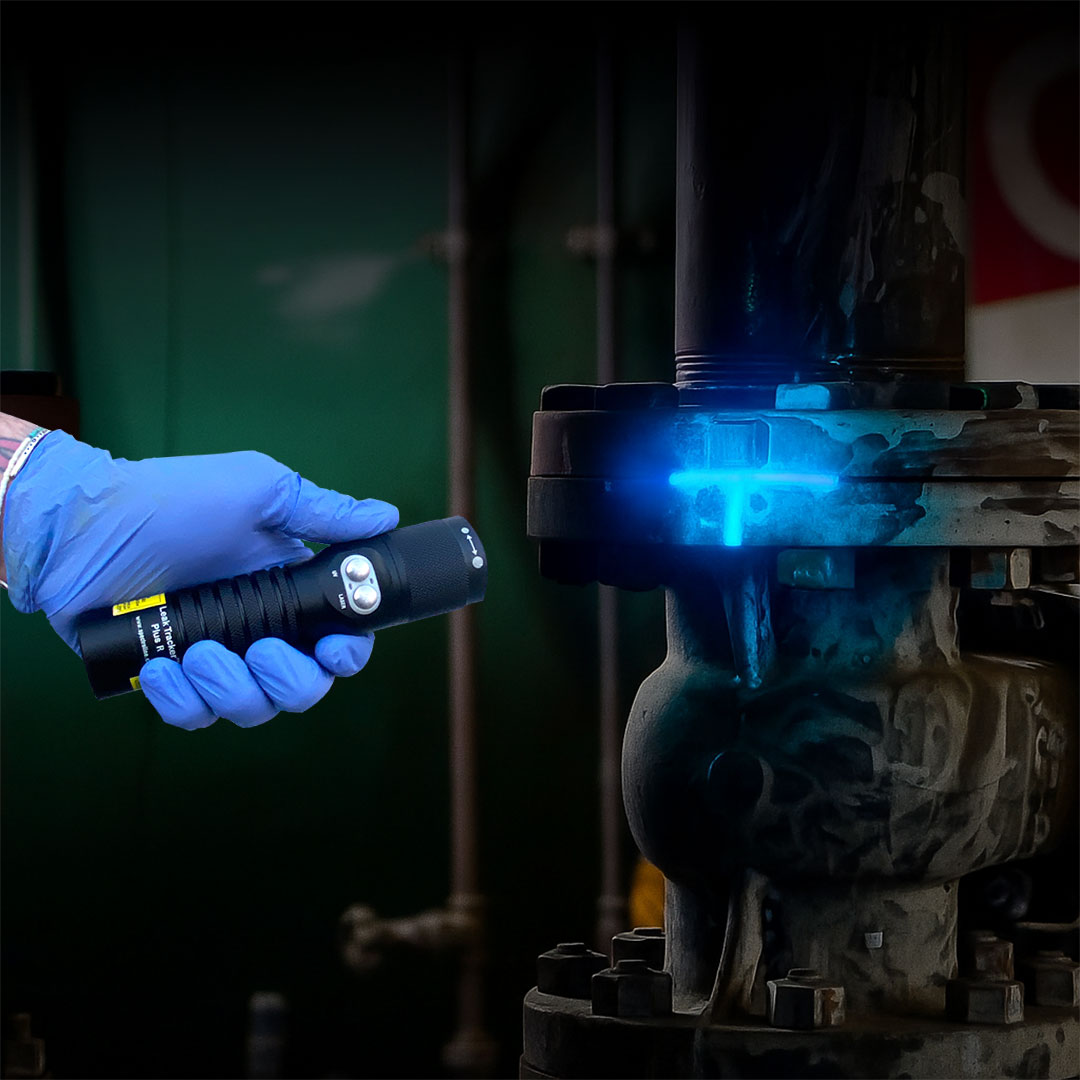

That’s why Spectroline’s OIL-GLO® Ultra Blue (SPI-OGB) is the ideal solution for silicone oil leak detection—helping you pinpoint even the smallest leaks quickly and accurately using UV light.

What is OIL-GLO® Ultra Blue?

OIL-GLO® Ultra Blue (SPI-OGB) is a powerful fluorescent leak detection dye designed to mix seamlessly with dimethyl-based silicone fluids. Once added to your system, the dye circulates with the fluid and becomes visible under a Spectroline UV inspection lamp, revealing leaks with a bright, glowing blue fluorescence.

✅ Safe & compatible with silicone-based heat transfer fluids

✅ Fast & accurate leak detection under UV light

✅ Non-disruptive to system operation

Why Are Silicone Oil Leaks Bad?

Silicone oil leaks can be problematic, especially in industrial and manufacturing environments. That’s one of the reasons why having a dependable leak detection method in place is essential.

1. Safety Hazards

-

Slippery surfaces: Leaked silicone oil is extremely slick, posing slip hazards for workers and creating unsafe working conditions.

-

Fire risk: While most silicone oils are not highly flammable, under certain conditions or in modified formulations, they can contribute to fires or hinder fire suppression systems.

2. Equipment Damage

-

System inefficiency: Loss of silicone oil affects system performance, especially in heat transfer, cooling, or lubrication applications, leading to overheating, increased wear, or system failure.

-

Component degradation: Leaks can compromise sensitive components, especially electrical systems if used as dielectric coolants.

3. Environmental Concerns

-

Contamination: Silicone oil leaks can contaminate groundwater, soil, or nearby ecosystems, particularly if they occur outdoors or near drainage systems.

-

Hard to clean: Silicone oils don’t evaporate easily and can coat surfaces, making cleanup difficult and requiring chemical degreasers or special disposal protocols.

4. Operational & Financial Costs

-

Downtime: Leaks often require systems to be shut down for inspection, repair, and cleaning.

-

Product loss: Silicone oils are expensive specialty fluids. Even small leaks can lead to significant fluid loss over time.

-

Regulatory fines: Leaks may trigger environmental or safety violations depending on the application and jurisdiction.

5. Undetected Leaks = Long-Term Damage

-

Cumulative degradation: Undetected leaks cause slow but steady performance degradation, often going unnoticed until a major failure occurs.

-

Preventable wear and tear: Addressing small leaks early extends system life and improves reliability.

How to Use Spectroline SPI-OGB for Leak Detection

-

Add the Dye

Mix 1 oz of SPI-OGB per 8 gallons of silicone-based fluid. Allow enough time to circulate, especially in high-viscosity systems. -

Use UV Inspection

Scan with a Spectroline UV lamp under low light. Even the smallest leaks will glow blue, since dimethyl silicone fluids do not fluoresce on their own. -

Check System Conditions

-

Optimal temperature: -20°C to 80°C

-

Ensure full fluid circulation before inspection

-

Why Choose Spectroline for Silicone Leak Detection?

-

Trusted globally for industrial and automotive leak detection

-

OEM-grade UV dyes engineered for safety and performance

-

Saves time, money, and risk by catching leaks early

-

Part of a preventative maintenance plan for long-term reliability

No size application is off limits. Choose between any of the sizes below:

We offer an Oil Analysis Kit (SPI-AK) which collects your oil sample and sends it in for a lab-tested Dye Recommendation Report. Email us at orders@spectroline.com or call (516) 333-4840 to get started!