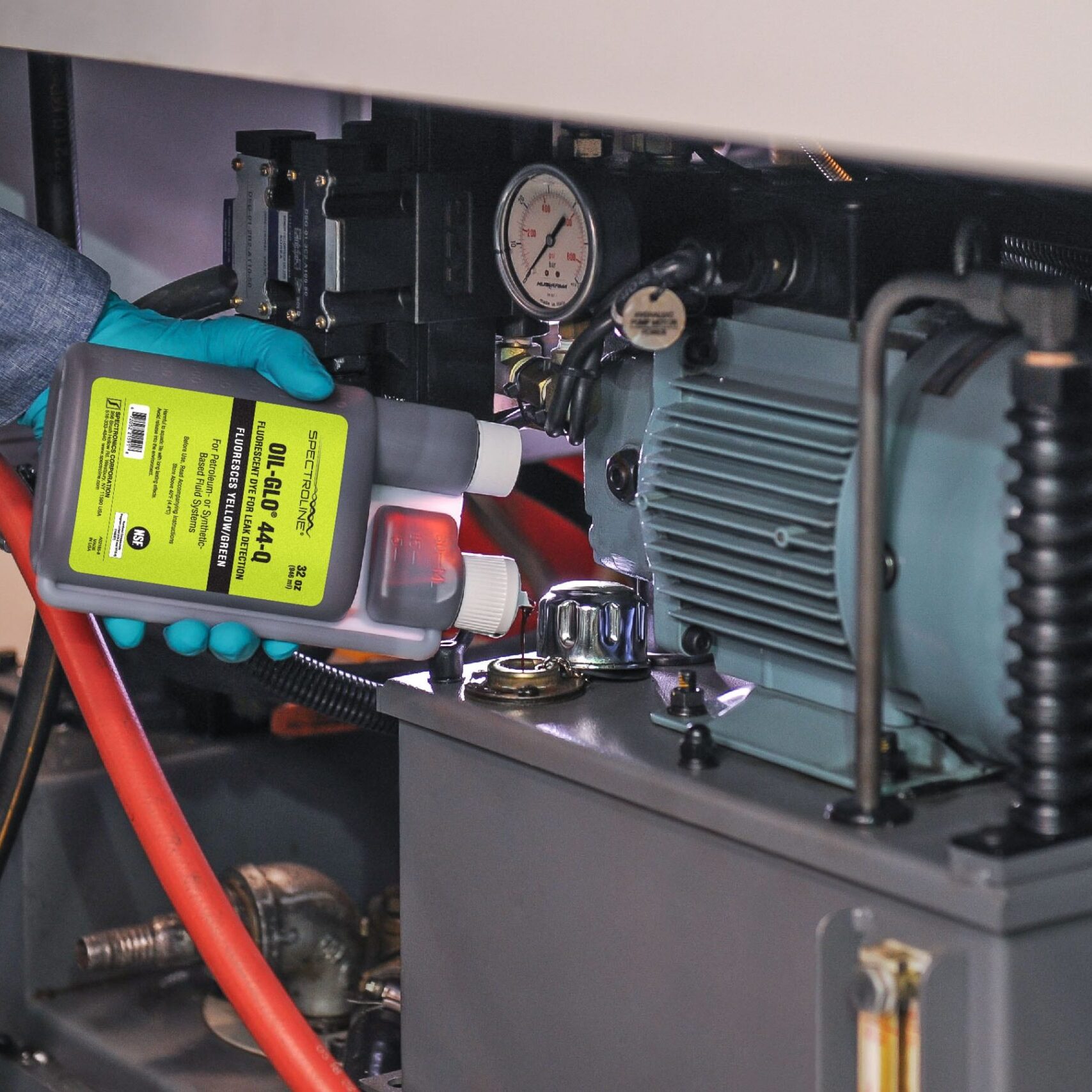

ARG Industrial Elevates Industrial Leak Detection Solutions Using Spectroline

ARG Industrial has been a Spectronics Corporation Partner since 2020 ARG Industrial was founded (formerly known as Alaska Rubber & Rigging Supply, Inc.) in 1980. The one store in Anchorage has grown through acquisition and expansion to five branches in Alaska, six branches in Washington, and one branch in Oregon. Visit their website to learn…

Details