What is Preventive Maintenance and Why Do It?

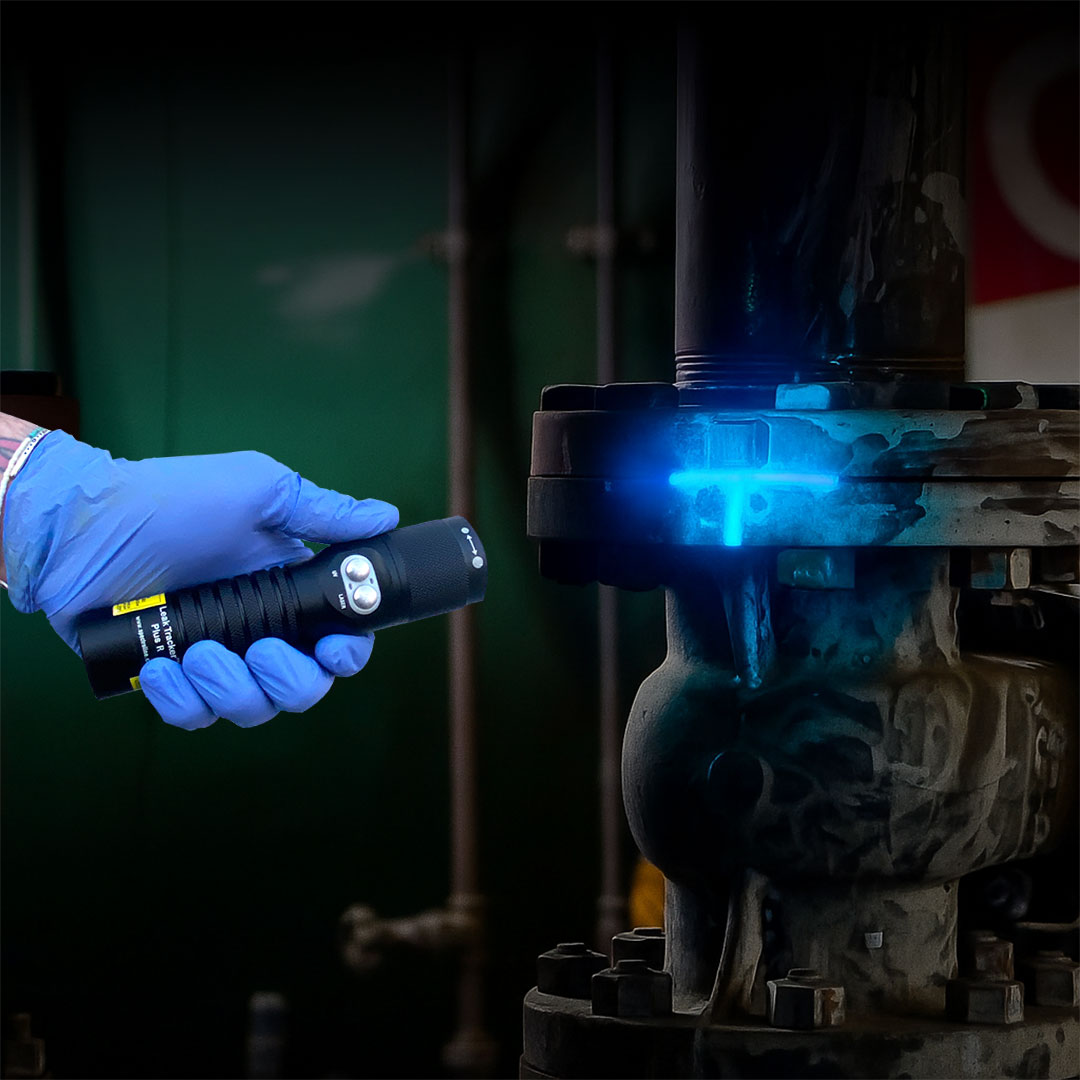

Preventive Maintenance for Hydraulic Equipment Preventive maintenance is a proactive equipment and system facilities management strategy. It operates on cost/benefit premise of creating a calendar of regularly scheduled testing and upkeep Typically, testing and maintenance are performed while equipment and systems are still in good working condition. This calendar set up can be based…

Details