Selecting an HVAC/R Fluorescent Leak Detection Lamp

When selecting the best fluorescent leak detection lamps it is important to know what features to look for in a lamp. UV lamps or torches are the best dye companion for finding and observing leaks in AC&R systems. Not all HVAC/R leak detection lamps are created equal and with many options on the market it can be challenging to select the right one. Ultimately, a quality lamp will create the best illumination possible for the appropriate application when paired with fluorescent dye.

Violet vs. Ultraviolet Light

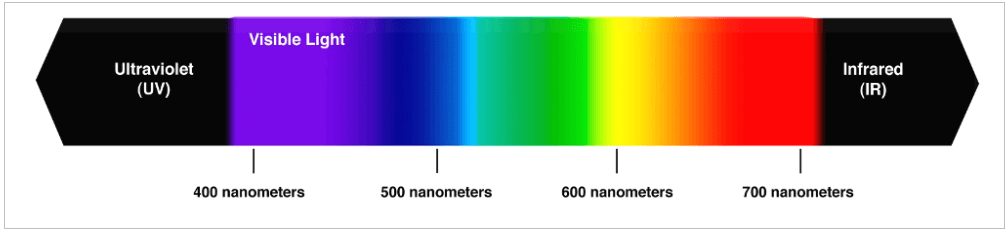

Violet and UV light are a form of electromagnetic radiation. Higher energy light is characterized as having shorter wavelengths. Some wavelengths are visible while others are not. Violet light is visible to the human eye. UV light is invisible to the human eye because it is of a higher magnitude of energy. When UV light is absorbed by fluorescent materials, the light is reflected as visible light. This is known to us as UV-induced visible fluorescence.

HVAC/R Leak Detection Lamp Qualities to Consider

The primary features of a leak detection lamp are the wavelength, beam profile and intensity. Fluorescent dye naturally glows under varying wavelengths, but for the best fluorescent results, Violet and UV light are used because they easily activate the fluorescent response. These wavelengths fall within the 300-400 nanometer range. This information is critical because leak detection lamps must be carefully engineered to provide a strong, consistent beam profile.

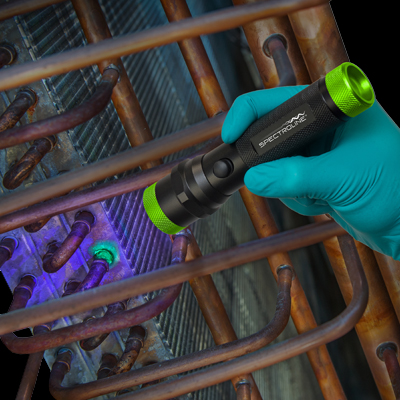

Beam profile and the intensity create the focused illumination to project the light. It is best for the beam profiles to be intense and carefully focused. To help capture the leaks with certainty the light beam should be designed to form an evenly lit spot at roughly a ½ meter distance. Secondary features matter as well when selecting a UV torch. This can range from portability, power options and style, like an anti-roll cuff or laser pointer.

Using Quality Dye with a Quality Leak Detection Lamp

As there are many lamps on the market, there are other dyes as well. To get the brightest leak detection response you want to use quality dye with a quality lamp. Dye fluorescence is dependent on the ratio of fluorescent material to carrier oil. Economy dyes typically have low levels of fluorescent material, making them lack the concentration necessary to give a good fluorescent response when exiting a leak site.

Additionally, a true quality dye is co-solvent free, fully miscible and has NSF certifications. Co-solvents can lead to premature wear or outright damage to system components. Choosing a dye that is co-solvent free, minimizes any potential compatibility issues. While selecting a product that is certified by NSF lets you know the company complies with strict standards and procedures imposed by the NSF organization.

When pairing a Spectroline® leak detection lamp and dye together it creates the optimal scenario for detecting the exact source of every leak. Spectroline® lamps are cordless and feature a compact design for getting into tight spaces, a durable lamp body and powerful, high-intensity LEDs. They can stand up to years of heavy use for continual leak detection inspections.