油圧漏れは時間とお金を盗む

作動油漏れの本当のコストは?作動油を失った場合のコストは、数万ドルにもなります。作動油ベースのシステムは、重要な作動油が十分にないと、すぐに故障したり、過熱したり、故障したりします。考えてみてください。装置が修理工場で立ち往生している場合、数千ドルの損失が発生します。その純収益には、賃金、許可証、修理費用、作業時間の短縮、機器の寿命の短縮など、すべてが含まれています。

Spectrolineは独自の液漏れ計算機を開発し、どのくらいのお金が失われているかを判断するのに役立ちます。 シンプルなインターフェースにより、ユーザーは漏水の正確なコストを見つけることができます。当社のデータは、業界をリードするレポートと当社独自のデータから編集されています。変数の一部には、漏れ箇所の数、漏れ率、流体粘度が含まれています。覚えておいてください:油圧漏れは、より大きな問題の症状です。お使いの機器の状態は、メンテナンスの質を反映しています。

年間リークコスト計算機油圧作動油の漏れに関する簡単な事実。

- 産業用機器は、その意図された使用に必要な量の 4 倍の液体を使用します。漏れを発見するのに時間がかかりすぎる場合、オペレータは失われた液体を交換するだけで、漏れを修理しないのが一般的です。

- 漏れがなくなれば、北米だけで年間1億ガロン(3億8千万リットル)以上の作動油を節約できる可能性があります。

- 1 秒間に 1 滴の油圧作動油の漏れは、年間 420 U.S.ガロン(1,600 L)の損失に相当します。1ガロン当たり5ドルの場合、この漏れのコストは年間約2,100ドルとなります。

小さな漏れであっても、機器に深刻な損傷を与える可能性があります。高圧力の油圧システムは、何か問題があればすぐに故障してしまいます。

作動油を紛失した場合の費用や、油圧システムを維持するためにできることについてお話しましょう。

油圧作動油の漏れの隠されたコスト

30年以上前にさかのぼって、業界の研究者は、機器の10%が全体のコストの90%を牽引していることを発見しました。これは主に機器のダウンタイムが原因です。 近年、資産管理者がリアルタイムで機器を評価する能力を持つことが求められています。集中監視ネットワーク(システム圧力センサーで構成)は、資産管理者を大いに助けてきました。しかし、業界全体としては、これらのコンピュータ化されたプログラムを普遍的に導入していません。

紫外線漏れ検知は、経済的で効果的で、簡単に追加できます。資産管理者は、クルーに定期的に機器をスキャンさせて、漏れている油圧作動油を素早く見つけることができます。2015年には、当社のクライアントは、4ヶ月以内に新たなしつこい漏れが23%減少したと報告しています。

時間が経つと、失われた作動流体を交換するための正確なコストを計算することが困難になることがあります。日々のスケジュールの中で、技術者は失われた作動油についてほとんど考えていません。作動油のレベルが少し低くなったら、作動油を追加しますよね?しかし、計算に入れていないのは、機器の耐用年数にわたって作動油を交換するためのコストです。あなたのチームが多くの機器を使用している場合、インベントリ全体の液漏れのコストを考慮していない可能性が高いです。手元の日々の問題を解決しているだけで、リアクティブ・メンテナンスに関連したより大きな負債を考慮していないのです。

漏れの一般的な原因

漏れの最も一般的な原因の一つは、不適切に取り付けられた部品や継手です。漏水の60%以上はヒューマンエラーや生産上の欠陥が原因です。これらのミスを避けるために、接続部と継手が確実に固定され、正しく取り付けられていることを確認してください。

水漏れの一般的な原因は、簡単に回避することができます。ここでは、メンテナンス計画の基礎を築くためのいくつかの出発点をご紹介します。

- 定期的にシステムの油圧を点検・検査してください。

- 液体レベルがメーカー推奨の設定になっていることを確認してください。

- 定期的に油圧機器を点検し、運転状態を記録するための予防保全計画を策定してください。

予防保全

予防的なメンテナンスは不可欠です。メンテナンスの目標を明確に設定することは、システムを確実に正常に稼働させ、修理工場への出向くコストを削減するための鍵の一つです。

失われた作動油を常に交換すると、汚染の可能性が高まります。粒子状物質や水の汚染は、油圧作動油の化学的特性に影響を与える可能性があります。油圧機器の寿命を延ばす上で重要なこれらの特性の変化は、機器の効率を低下させます。

密閉された油圧システムを維持することは、機器の安全な操作と長寿命を維持するために最も重要です。油圧作動油に混入した汚染物質や、システムから流出した油圧作動油は、システムを劣化させ、運転上の不具合につながる可能性があります。

油圧システム内のすべての部品は相互に依存しているため、1 つの部品が故障すると全体の性能が損なわれる可能性があります。油圧システムは、リザーバ、ポンプ、バルブ、作動油、モーター、ホース、フィルター、シリンダーで構成されています。これらの部品の間の微妙なバランスが、油圧機器が掘削や解体などのヘビーデューティーな作業を行うことを可能にしているのです。

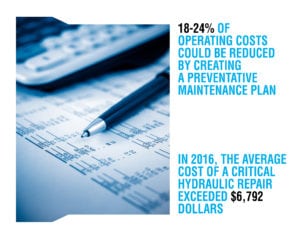

2017年には、定期的な予防保全を実施することで、全体の運転費用を27%も削減できることが示されました(完璧に実行した場合)。集中型の電子監視システムに容易に統合できない機器については、PM計画の採用により、運用コストが大幅に削減されることが示されています。

予防保全について詳しく知りたい方は、こちらをご覧ください。 https://spectroline.com/creating-a-preventative-maintenance-plan-for-hydraulic-systems/

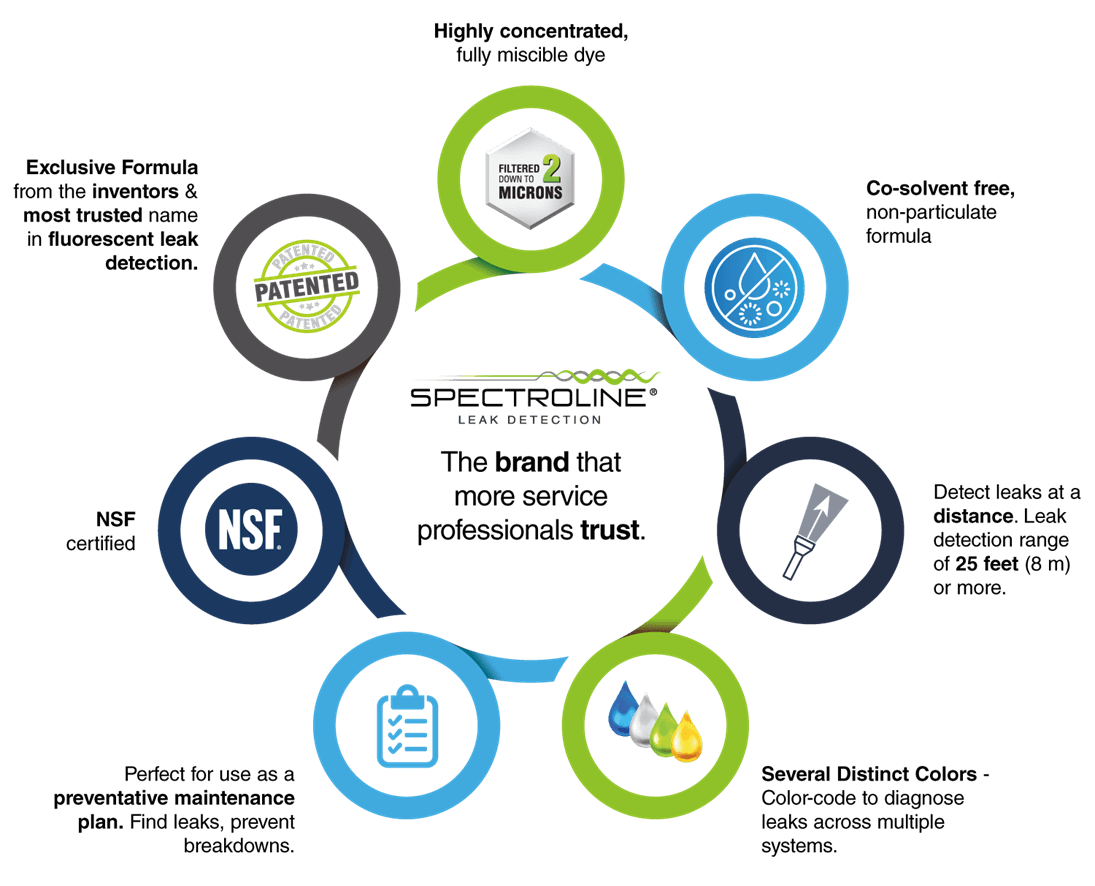

適切な漏れ検出ツールを使用することで、機器の品質を維持し、耐用年数を延ばすことができます。早期の消耗を防ぎ、ダウンタイムを防ぐことができます。Spectroline® 紫外線蛍光漏れ検出法は、安全かつ非侵襲的に数分以内に漏れを検出します。

紫外線リーク検出方法

2018年の調査では、回答者の87%が紫外線蛍光色素を活用することで(他の漏水検知方法よりも)より早く漏水を検知できたと回答しています。回答者はまた、漏水を発見して修理しようとする時間を半分に短縮できたと報告しています。

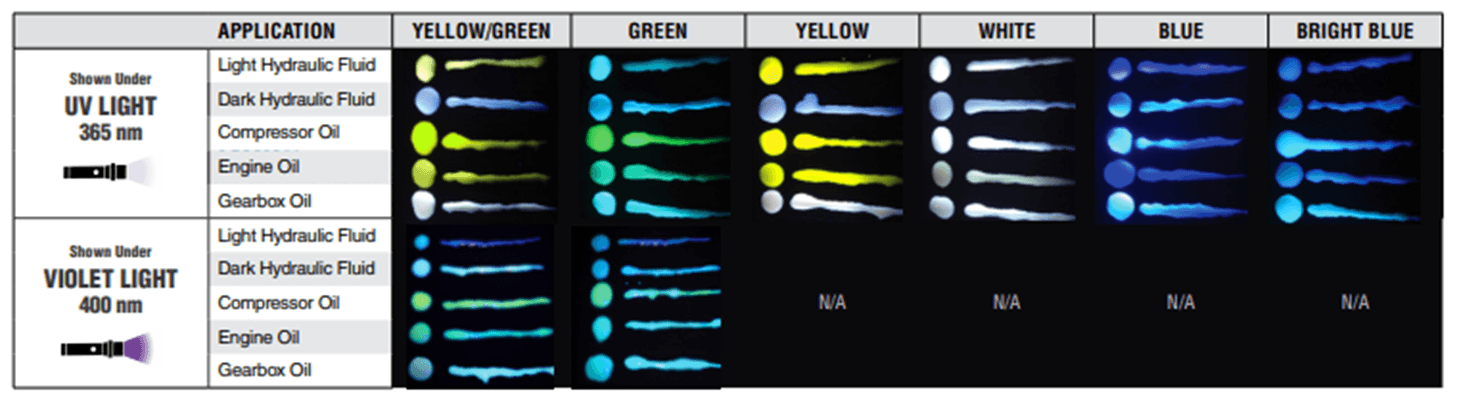

Spectroline®方式の紫外線によるリーク検出は、シンプルで非侵襲的であり、機器の保証を無効にすることはありません。その仕組みは次の通りです。Spectroline® 紫外線染料が油圧システムに入り、循環してシステム全体に浸透します。もし漏れがあれば、染料はホストの油圧作動油とともに排出されます。紫外線リークディテクターのフラッシュライトでシステムをスキャンすると、蛍光染料が反応して鮮やかに光り、すべてのリークの正確な位置を明らかにします。Spectroline® は、安全性と性能に関する最新の業界基準をすべて満たすために、開発、テストに多大な努力を払っています。Spectroline® dyeは、油圧システム内に安全に留まることができ、予防的メンテナンス計画の一環として使用される完璧な診断ツールです。これらの染料は、業界のリーダーたちに信頼されており、Caterpillar®、General Electric®、John Deere®など、世界の主要な油圧機器メーカーの多くにOEM承認されています。

Rosenboom®のGary Wachter氏は次のように述べています。 油圧シリンダのメーカーとして、当社の溶接プロセスの完全性は非常に重要です。当社では製品を100%テストしていますが、Spectroline OIL-GLO®染料と検査ランプを使用することで、溶接接合部に存在する可能性のある漏れをより簡単に特定できることがわかりました。これらの製品を何年も使用していますが、その性能には非常に満足しています。

継続的な成功

実行可能な予防保全計画と組み合わせた紫外線漏れ検出により、油圧機器のオペレータは、1台あたり数千ドルの節約に成功しました(作動油の漏れが機器の故障の原因であると判断された場合)。予防保全計画を実施するための総投資額は、企業の総運転予算の1%未満でした。

お客様にアンケート調査を行った結果、当社の製品を使用することで、お客様は油圧作動油の損失だけで年間平均800ドルの節約ができたと判断しました(中型から大型の油圧機器の場合)。破損した重要部品の交換にかかる平均コストは6,792ドル(修理する部品によって異なります)を超え、お客様は1年間を通じて生産コストと運転コストを少なくとも15%節約することができました。

OIL-GLO ウルトラ・コンプリート

スペクトロラインOIL-GLO ULTRA コンプリート」は は、以下のようなすべての油性流体システムの漏れをピンポイントで検出する紫色光蛍光式漏出検出キットです。 油圧システム、コンプレッサー、エンジン、ギアボックス、燃料システムなど。 キットを使用するには、疑わしいシステムにOIL-GLO ULTRA蛍光漏れ検知用オイルダイを加え、キットに含まれるバイオレットライトLED漏れ検知用フラッシュライトで漏れ箇所をスキャンします。蛍光染料は、潤滑、油圧、冷却制御、または静水圧試験に流体が使用される密閉システムで機能します。 精密に設計された処方で、システム内に安全に留まり、将来の漏水検知検査に使用することができます。

油圧漏れの早期発見

作動油の漏れを早期に発見することは、コスト削減につながります。1秒間に1滴の作動油の漏れは、1年間に420米国ガロンの損失に相当します。1ガロンあたり5ドルとすると、この漏れのコストは年間で約2,100ドルになります。

スムーズな作動油システムを維持するためには、漏れの検出が不可欠です。オイルや作動油などのシステム液が少ないと、機器の動作に影響を与えたり、内部部品の磨耗を増加させたりすることがあります。このリーク検出キットは、高価な機器の故障を防ぎ、ダウンタイムによる人件費を削減し、環境汚染の防止に役立ちます。漏れがなくなれば、北米だけで毎年1億ガロン以上の油圧作動油が節約できると推定されています。

スムーズな作動油システムを維持するためには、漏れの検出が不可欠です。オイルや作動油などのシステム液が少ないと、機器の動作に影響を与えたり、内部部品の磨耗を増加させたりすることがあります。このリーク検出キットは、高価な機器の故障を防ぎ、ダウンタイムによる人件費を削減し、環境汚染の防止に役立ちます。漏れがなくなれば、北米だけで毎年1億ガロン以上の油圧作動油が節約できると推定されています。